One of the best gifts we received from Casie's family was the Gus Modern Sparrow glider — and we've received many complements on it. It's a beautiful chair and Casie swears by it for getting the boy to sleep.

However, today, Casie and Truman sat in it and it broke. When I investigated, I found an amazingly shoddy assembly using sub-standard and inappropriate joinery*.

*I should add that I don't think that this was Gus' intention (they're a decent outfit), but quality control and offshore manufacturing are hard to balance, it seems… and this post was created simply as a convenient place to house the information so that Gus can take a look-see. Ironically, both the solid walnut base and the steel rocking mechanism were of extremely high quality, but the joinery between the two is suspect to say the least.

Edit: I received a response from Gus*: "Thank you for getting in touch with us and letting us know you had issues with the Sparrow Glider. We will pass along all information, including your detailed pictures, to our design team. We take these matters very seriously and appreciate you taking the time to inform us of this issue. Gus*"

Interestingly enough, though, I'm not seeing the word "sorry" in the above.

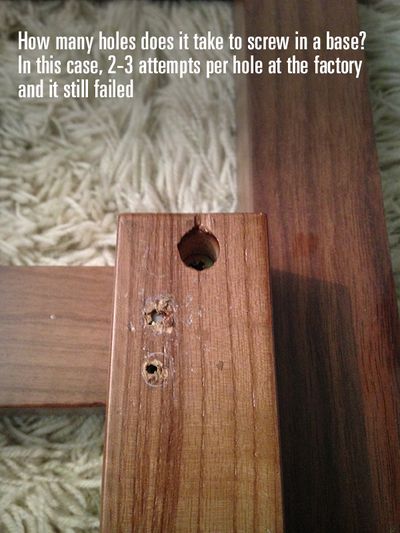

More specifically, the three screws that were holding one side of the frame sheared off. This left the base completely unsecured. When I removed the base from the chair, I found that someone — presumably at the factory — attempted to screw in the base a few times and failed… there were 2-3 times as many screw holes as necessary — some at odd angles.

Additionally, the screws used were very short, light-duty wood assembly screws that are great for simple wood-to-wood joinery, but completely inappropriate and undersized for this application. A #10 flat-head screw at minimum should have been used, but instead the #8 bugle-head screw created too much tension at the head — and when the head was wedged into the over-sized hole, it created a perfect shear-off situation.

When screwing/bolting steel to wood, you want a flat mating surface and a hole that doesn't have too much (if any) wiggle. Bugle-heads are made to sink into wood (or drywall)… unfortunately, there's no sinking into a steel plate, especially into an over-sized hole. In one case, it looked like they ran out of the #8s and used a single #10 instead… (sigh).

The result was an unstable chair sold as a mainstay of the nursery world — a bad combination.

In the end, since the holes in the mechanism were too big and the holes in the base were already compromised, I drilled new holes in the steel mechanism sized for the appropriately designed and fasteners that I had on hand and I reassembled the chair… sure, no big deal, but I'm a furniture-builder and it still took me 1/2 hour (and I had the materials and tools on hand, specifically the correct fasteners and extensions for both drilling and screwing as the tight fit would have not worked for a typical drill). The repair definitely wasn't a homeowner DIY job much less something that a new mom (or dad) should need to deal with on a $1000+ chair.

Here's a video clip…